With the acceleration of urbanization process and the increase of infrastructure investment, PE carat pipe, as an important branch of high-density polyethylene pipeline, will show significant technological iteration and market pattern evolution in 2024. The industry as a whole presents three development directions of intelligence, environmental protection and efficiency.

At the technical level, the multi-layer co-extrusion production process has achieved breakthroughs. The application of new modified materials and nano-enhanced technology has increased the ring stiffness and impact resistance of pipes by about 30%. Intelligent monitoring systems are widely implanted in the production line, and the product defect rate is controlled below 0.2% through real-time sensor data feedback. The weather-resistant formula developed by some enterprises can extend the service life of pipelines in extreme environments to more than 50 years.

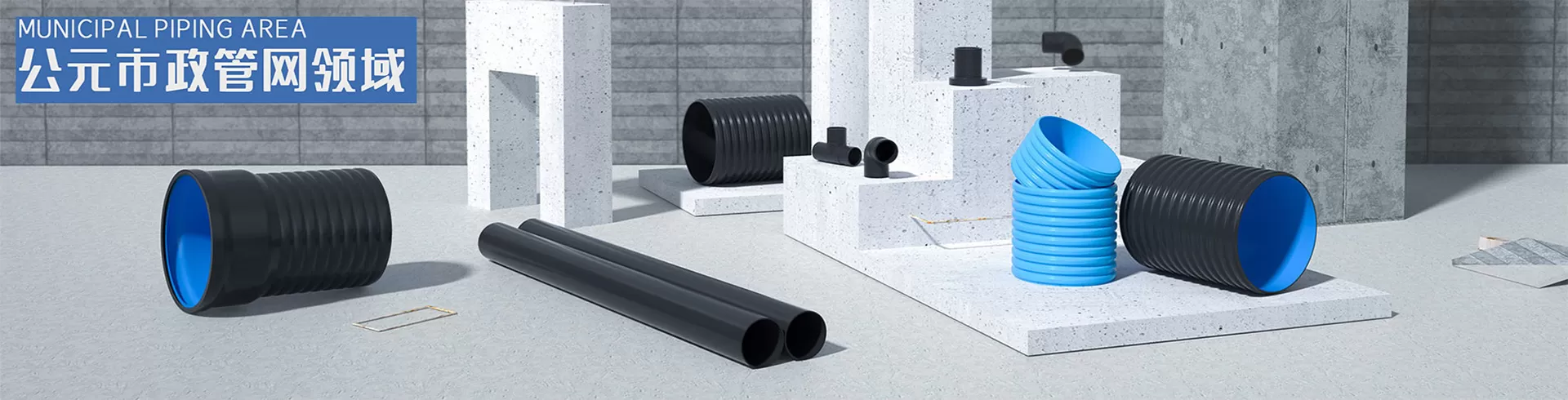

The market demand structure has changed significantly. The traditional municipal drainage field still accounts for more than 60% of the share, but emerging application scenarios are growing rapidly. Sponge city construction projects have driven the demand for large-diameter (above DN1200) carat pipes to increase by 24% year-on-year, and the supporting pipe network system of photovoltaic power stations has become a new growth pole. Lightweight and modular pipe solutions are more favored in rural sewage treatment projects.

The tightening of environmental protection regulations promotes the green transformation of the industry. The "Green Product Evaluation Specification" implemented from 2024 requires that the proportion of recycled materials in pipeline products is not less than 20%, which prompts enterprises to speed up the establishment of closed-loop recycling systems. The R & D investment in bio-based polyethylene raw materials has increased by 45% compared with last year, and some demonstration projects have achieved a 40% reduction in carbon emissions in the whole life cycle. 1172779 Raw material price fluctuations still affect the industry's profit margins, but cost optimization brought by intelligent manufacturing can offset some of the pressure. Third-party testing data shows that the market penetration rate of products meeting the new national standard GB/T19472.2-2023 has reached 78%, and technical barriers continue to rise.

In the future, the industry will focus on the development of customized solutions, such as low-temperature resistant pipes for permafrost areas and high-flexibility connection systems for seismic zones. The digital twin laboratory jointly established by the industry and academia is accelerating product iteration by simulating the service environment, injecting continuous innovation into the industry.

.jpg)