As an important plastic pipe, PE carat pipe is widely used in many fields. In order to help you better understand and use it, we have sorted out 10 most frequently asked questions and answered them.

1. What is PE carat pipe?

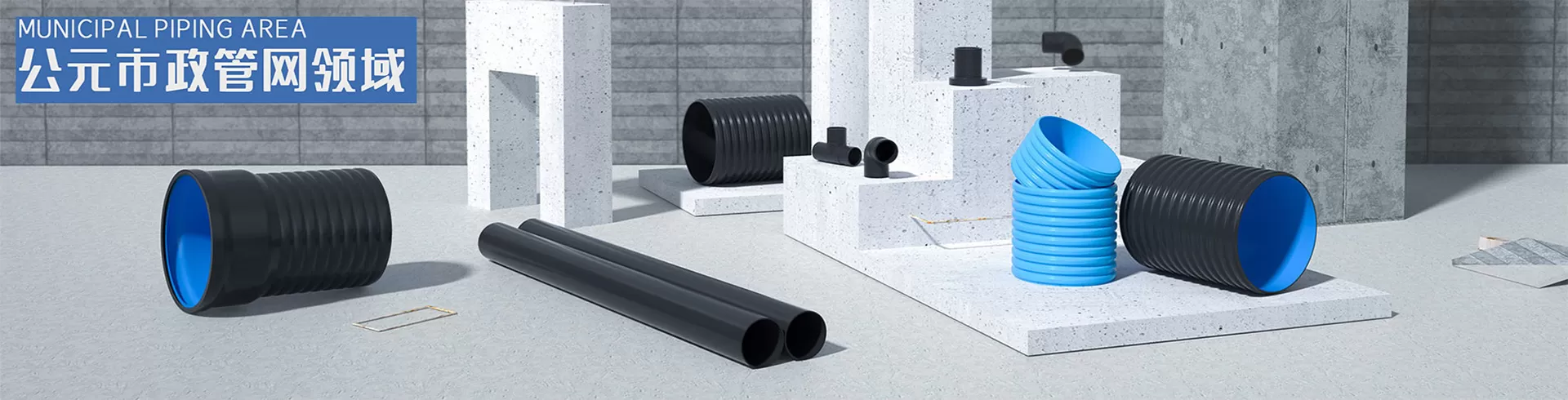

PE carat pipe is a plastic pipe made of high-density polyethylene (HDPE) as the main raw material through hot winding molding process. Its inner wall is smooth, and the outer wall is a spiral corrugated structure. This unique structure gives it excellent external pressure resistance and flexibility, making it especially suitable for underground drainage, sewage and other gravity flow conveying systems.

2. Where is PE carat pipe mainly used?

It is widely used in municipal drainage, rainwater collection systems, infiltration and drainage of highways and railways, sewage discharge of residential areas and factories, irrigation of farmland water conservancy, and sheathed pipes of power and telecommunications cables.

3. How to install PE carat pipe?

Installation usually adopts the way of digging trenches. First of all, it is necessary to ensure that the bottom of the trench is flat, tamped, and there is no sharp debris. Then it is laid according to the design elevation, and backfilled after the pipeline connection is completed. Backfill material should be sand or original soil, but hard objects need to be removed and tamped in layers.

4. How is PE carat pipe connected?

Its core connection method is "socket electric hot melt connection". One end of the pipe is the socket of the flare, and there is an electric heating wire embedded inside. When connecting, insert the flat end of another pipe into the socket, and heat the electric heating wire through a special electric hot melt welding machine to melt the PE material of the socket and the socket end into one, and form a firm, sealed and leak-free connection point after cooling.

5. What are the specifications and models of this pipe?

Its specifications are usually expressed in the outer diameter (DN/ID), such as DN200, DN300, DN400, DN500, DN600, DN800, etc., and larger specifications can even be above DN2000. At the same time, ring stiffness (SN) is also a key indicator. Common grades are SN8, SN10, SN12.5, SN16, etc., to characterize the ability of the pipeline to resist external pressure, which needs to be selected according to the depth of burial and ground load.

6. How long is the service life of PE carat pipe?

Under the specified construction conditions and normal use environment, the design life of high-quality PE carat pipe can reach more than 50 years. This is due to the excellent corrosion resistance, wear resistance and anti-aging properties of HDPE materials.

7. What is its approximate price?

The price is not fixed, it will be affected by various factors such as raw material price fluctuations, pipe specifications (diameter and ring stiffness), purchase quantity, transportation distance and market supply and demand relations. Therefore, to obtain an accurate quotation, specific technical parameters and requirements need to be provided to the supplier.

8. What are its advantages over concrete pipes?

Compared with traditional concrete pipes, PE carat pipes are light in weight, which greatly reduces the difficulty and cost of transportation and construction; their flexibility is good, the foundation is adaptable, and the ability to resist uneven settlement of the foundation is better; the inner wall is absolutely smooth, the water flow resistance is small, and the conveying efficiency is high; and its acid and alkali corrosion resistance far exceeds that of concrete pipes, and the service life is longer.

9. What should be paid attention to when purchasing?

When purchasing, you should pay attention to: Confirm whether the required specifications (diameter and ring stiffness) match the engineering requirements; Check the appearance of the product to ensure that there are no defects such as bubbles, cracks, and obvious impurities; Ask the supplier to provide a qualified inspection report; Select a reputable and quality guaranteed manufacturer.

10. What are the requirements for storage and transportation?

Pipe should be handled with care during transportation and loading and unloading to avoid severe impact, throwing and dragging. The storage site should be flat and the stacking height should not be too high to prevent the bottom pipe from being over-compressed and deformed. At the same time, it should be kept away from fire sources and avoid long-term sun exposure.

.jpg)